Motorsports Racing News & Blog Articles

WORLD EXCLUSIVE: Ducati V21L MotoE Prototype – First Look

Ducati has finally released details about its much-anticipated electric race bike, known internally as the “V21L” prototype. The V21L is important for several reasons. Not only is it the platform with which Ducati will tackle the MotoE championship, starting in 2023 as the sole supplier, but it can also give us some clues as to some of the solutions Ducati are experimenting with in regards to a future production-based electric motorcycle available to all.

More important still is the fact that Yours Truly got an exclusive invite to look at, touch, and sit on the V21L, making me the first person outside Ducati given the chance to do so. My impressions of the bike – and Ducati’s official press release – will follow, but first, the details.

The Specs

Ducati is tackling the MotoE project as it would a production bike, employing its Centro Stile (Design Center) and engineering teams concurrently to rapidly design and develop the V21L to Dorna’s specifications (and beyond). Unsurprisingly for a project like this, the engineering team includes members of both Ducati Motor Holding and Ducati Corse, the competition arm of the factory involved in every aspect of Ducati’s racing efforts, including MotoGP.

The MotoE project is comprised of staff from both Ducati Motor Holding and Ducati Corse. The latter is identified by their red clothing.

The MotoGP connection is important because, from the outset, the V21L’s electronic systems needed to operate just as effectively and efficiently as Ducati’s Desmosedici MotoGP racer. Of course we’re talking about the use and implementation of Ducati Traction Control, Ducati Slide Control, and Ducati Wheelie Control (among others), but at a more granular level Ducati Corse engineers helped dictate the output of power from each degree of throttle rotation to closely mimic that of the MotoGP machine.

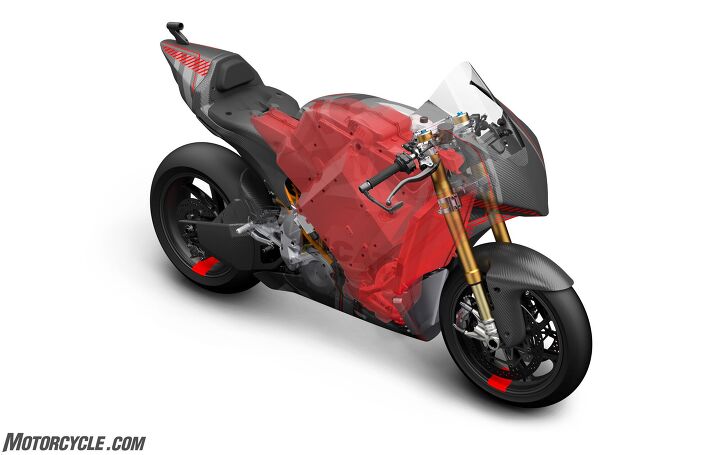

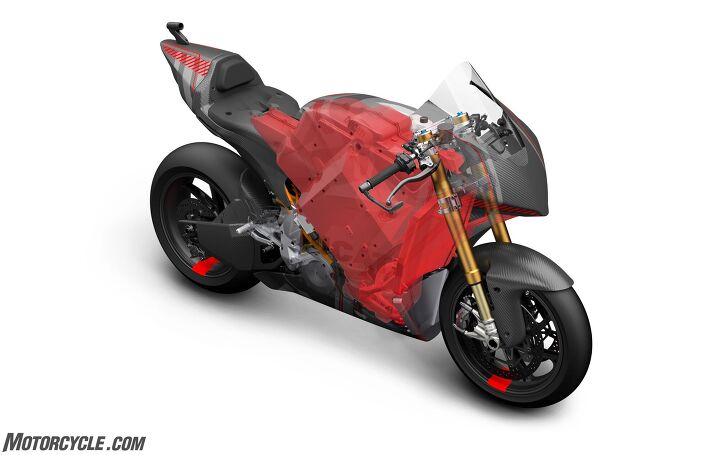

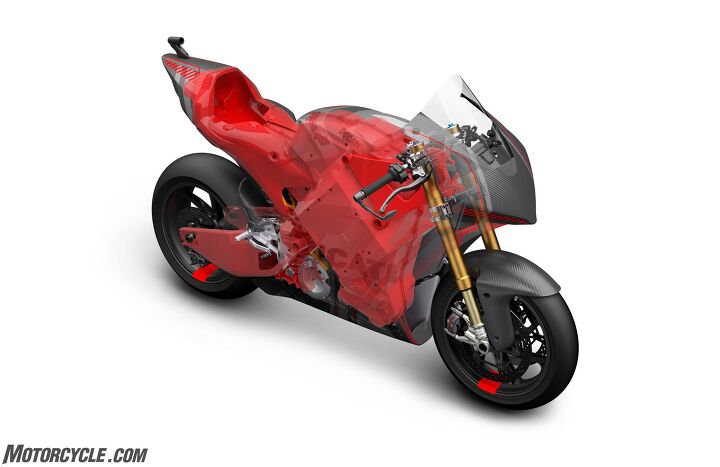

Of course, the natural question is: How much power does it make? According to Ducati, the MotoE racer has an output of 110kW (roughly 150 horsepower) and 140Nm of torque. As for the battery pack, it’s comprised of 1,152 cylindrical 21700 type cells – the same cells you’ll find in a Tesla. It weighs 242.4 lbs. (110 kg) and has a capacity of 18 kWh. What’s interesting about the pack is its orientation – tilted back within the chassis – and the fact it’s not a purely rectangular shape but rather a complex shape meant to fill the void within the middle of the bike. Naturally, it’s housed in carbon fiber, and like the Panigale V4 production bike, it’s attached to a front subframe, making it a stressed member of the chassis.

Shown in red is the battery housing. Notice that it’s tilted rearward not entirely unlike some internal combustion engines in motorcycles (though not to this degree). Most of the housing contains battery cells, but wedged in between there is the circuitry for liquid-cooling. Note the radiator and associated cooling system in front of the battery.

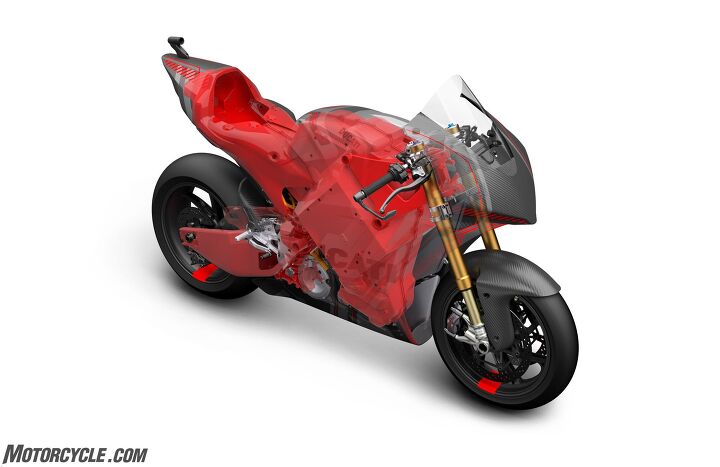

Weighing in at 11 lbs (5 kg), the unnamed inverter is a common unit, according to Ducati, found in other forms of electric vehicle racing. The motor, meanwhile, is a bespoke Ducati design weighing 46 lbs (21 kg) and can spin up to 18,000 rpm. It’s manufactured by an unnamed supplier. Roberto Cane, Ducati EMobility Director, confirmed the motor employs a gear reduction system, which is also evidenced by the “normal” size of the rear sprocket. Finally, the high voltage 800v system is similar to other high-performance electric vehicles, allowing for less current draw. But it also makes for a complicated system to control and insulate from.

Heat is the enemy of performance, and nowhere else is that more evident or important than on the track. In order to manage the heat to both the battery and the motor/inverter, Ducati has employed two separate liquid-cooling circuits – one for each system. The large central radiator keeps battery temps under control, while the smaller triangular heat exchanger beneath it does the same for the motor and inverter. Together, the two radiators look like they’re plucked directly from the Ducati Corse MotoGP or WSBK shelves.

Below the battery lies the inverter (left), motor (bottom center), and secondary radiator and cooling system. It’s not clear in this illustration, but the cables from inverter to motor are thick and robust – a necessity for an 800v system.

Keeping components cool not only offers consistent performance benefits on track but also off-track as well, as the MotoE bike can be charged directly after coming off the track. The robust cooling system means there is no wait time before being able to plug into the V21L’s 20-kW charge port located in the tail section. Ducati claims the bike can recharge to 80% in 45 minutes.

Because the battery pack takes up a significant amount of weight, every effort is made to reduce weight elsewhere. The front subframe is an aluminum piece weighing 8.2 lbs (3.1 kg), the rear subframe integrating the rider’s seat and tail section is all carbon fiber, and the swingarm is made from lightweight aluminum and weighs a tick over 10 lbs (4.8 kg). Interestingly, it also incorporates the same rear-end geometry as the Desmosedici MotoGP bike.

The additional items in red to pay attention to here are the front subframe, rear subframe, and swingarm/rear suspension. All are made from lightweight materials (either aluminum or carbon fiber) and in the case of the swingarm, copies the rear geometry of Ducati’s Desmosedici MotoGP racer.

The suspension features an Öhlins NPX 25/30 pressurized fork with 43 mm diameter upside-down tubes at the front, derived from the Superleggera V4, while an Öhlins TTX36 shock absorber is present at the rear and is fully adjustable. Because of the MotoE’s heavier weight, we think it’s a safe assumption these production-derived components have stiffer springs and revised damping to account for the weight difference. The steering damper is an adjustable Öhlins unit.

Stopping this 500 lb (224.5 kg) beast from the rapid speeds it can attain are some beefy components from Brembo. First off, you have two enormous steel discs at the front measuring 338.5mm. Looking at them with my own eyes, they’re thick, too. Ducati won’t tell me how thick though, possibly because it’s still in development. Brembo’s T-slot rotors also allow a little extra cooling material while keeping the full floating design of the discs. Two GP4RR M4 32/36 calipers with PR19 x 18 radial master cylinder work in tandem with the double discs. At the rear is a P34 caliper. Because there are no gears to shift, a clutch lever isn’t needed, meaning teams can purchase an optional rear brake lever to position on the left handlebar, like a scooter, which the rider can use as an alternative to the pedal for the right foot.

The Volkswagen Influence

Some may find it surprising to see a small company like Ducati stepping up to the plate as the first major manufacturer to produce a full-scale electric racing motorcycle as a stepping stone to a future production model. However, let’s not forget that Ducati is a part of the Volkswagen group. As part of the group, Ducati is following the parent company’s “New Auto” 2030 strategy, which is anchored on electric mobility being the future. As such, it makes sense within Ducati’s DNA to not sit idly by and watch, but instead to tackle the e-mobility challenge with every resource available to it within the Volkswagen umbrella. This obviously includes the VW Group’s centers of expertise and the Center of Excellence (CoE) at Salzgitter in Germany, but also with other brands of the Group such as Porsche and Lamborghini.

What’s It Like…To Sit On?

For those of you who don’t know, I’m involved in a side project as the test rider for the Lightfighter electric race bike (and I also wrote about it here, here, here, here, and here), so naturally, my interest in the Ducati MotoE bike is very high. Because of this, while in Italy for the Streetfighter V4 SP launch, I begged and pleaded to be able to ride the MotoE machine (it just so happened the test team would be at Mugello during my visit). Not surprisingly, my request was immediately shot down. (A quick aside: During the MotoE test at Mugello I learned the amount of Ducati Corse staff on hand. There’s one chassis engineer, one battery engineer, and the rest of the staff – roughly 15 people – are focused solely on electronics.)

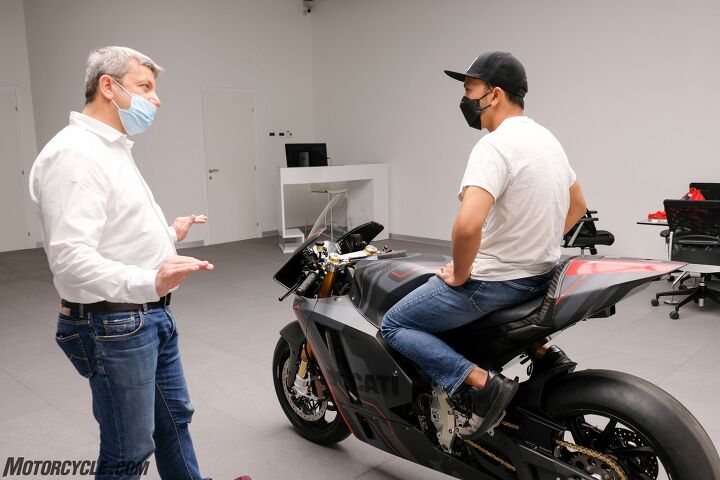

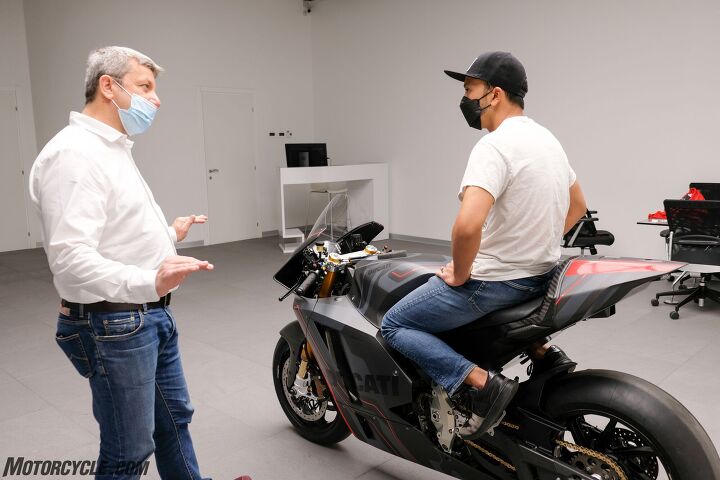

Anyway, a bone was thrown my way when I learned I’d be allowed to see the bike up close the day after the test, making me the first person outside of Ducati allowed such privilege. Not only could I look at it, but I’d also be able to touch and sit on the bike – but only on a stand.

Clearly, there’s only so much you can learn sitting on a bike atop a stand, but what I’m completely blown away with is the ergonomics. Bear with me here. Loosely speaking, the MotoE bike was designed to closely mimic the Desmosedici MotoGP machine in terms of dimensions, profile, geometry, and even aesthetics. While I’ve never sat on the Desmo before, sitting on the V21L, it’s as though the Centro Stile took my precise measurements into account when carving each little crevice in the tank’s shape.

Roberto Canè, Ducati eMobility Director, was kind enough to give me the tour of the MotoE project and answer all my questions. Or at least the ones he was allowed to.

My knees fit precisely into the curvatures in the tank, not only making the bike feel narrow (helped also by the svelte junction where seat meets tank) underneath me but also giving what I imagine to be a wide area of support for the rider to brace themselves on the brakes. It also serves as a large support to hook the outside leg in a corner. In a tuck, the slope of the tank provides a nice resting place for the arms, while the foam pad in the center of the tank was perfectly placed for my chin. As I moved back in the seat, the natural expansion of the saddle also lifted me up slightly to create a seemingly straight line for air to flow over the windscreen, past my body, and cleanly exit past the tail.

For as large of a bike as it is, another key ergonomic element was to place the pegs as close together as possible. According to Cane, this gives the rider a sense of narrowness with the bike, but is also something these top-caliber riders prefer in order to get maximum leverage and ground clearance.

The attention to detail is at such a high level, in a way it’s remarkable the V21L is still considered a prototype. Another example is seen – or felt, rather – at the swingarm. While running my hands along its contours I tried rubbing my fingers together through one of its relief points. I could have sworn my fingers almost touched, the wall thickness was so thin. Lateral flex is a sweet science race teams dedicate so much energy to in order to get right, and considering how heavy the rest of the bike is, to discover this small section of swingarm felt so thin and flexible in order to achieve a certain amount of flex and feel for the rider, was eye-opening.

All this and I haven’t even ridden the bike. Who knows if that day will come, but one thing’s for sure – Ducati isn’t tip-toeing into the 2023 MotoE championship. Expect records to fall quickly.

You can see Ducati’s official press release below.

Begin press release:

Ducati MotoE prototype details revealed: expertise for the future developed through racing

Ducati unveils the technical details of the MotoE project in a video in which the prototype is illustrated by the team that has overseen its creation and is following its development (direct link to see the video here).

“V21L” in Borgo Panigale identifies Ducati’s first electric motorcycle, a prototype that starting from 2023 will compete in the FIM MotoE World Cup, of which the Bologna-based motorcycle manufacturer will be a partner as sole supplier with 18 bikes on the track during each race weekend.

World Cup, of which the Bologna-based motorcycle manufacturer will be a partner as sole supplier with 18 bikes on the track during each race weekend.

The MotoE project has strategic relevance for Ducati since it makes it possible to develop expertise for the future while maintaining the approach that has always fuelled the DNA of the Bologna-based manufacturer: experimenting with technological solutions in the world of racing and working to ensure that everything that is developed in this area can then transfer to motorcycles destined for enthusiastic Ducatisti from all over the world.

Claudio Domenicali, Ducati CEO: “A few weeks ago I had the extraordinary opportunity to ride the Ducati MotoE on the track and I immediately realized that I was living in a historic moment. The world is going through a complex period and environmental sustainability is an element that all individuals and all companies must consider a priority if we want to preserve the delicate balance of the planet. As Ducati, we have grasped this need and we went in search of a challenge that would allow us to contribute to the common goal of reducing CO₂ emissions and at the same time to keep faith with our DNA linked to racing. We agreed with determination to develop the most performing electric racing bike that current technology makes possible and to use this project as a laboratory in which to build our future. The result we have achieved is surprising. As soon as I sat on the bike I realized the quality of the work done by the team and when I returned to the garage I felt a deep sense of pride for what we were once again able to achieve”.

To produce the MotoE prototype, the Bologna-based motorcycle manufacturer put together a team that unites Ducati and Ducati Corse designers, creating a truly extraordinary mix of skills. The creation of the bike followed the procedure that is usually adopted for production bikes, triggering a close collaboration between the members of the team that led to new ways of thinking and designing, encouraged by such a technologically challenging project.

The division of tasks and the continuous dialogue between the people who make up the team were fundamental throughout the process. Ducati R&D took care of all the Project Management activities, together with the design and simulations on the electric powertrain, while the design of the MotoE was taken care by the Centro Stile Ducati which also created the livery of the bike. Ducati Corse, on the other hand, worked on the electronic parts design, on the software controls and strategies, on the simulations of the dynamics and aerodynamics of the motorcycle, and finally on the bike assembly, testing, and data acquisition processes.

The result to date is already satisfactory: the Ducati MotoE has a total weight of 224,5 kg (12,5 kg less than the minimum requirements imposed by Dorna and FIM for a bike capable of completing the race distance) and can count on maximum power and torque figures of 110 kW (150 hp) and 140 Nm respectively, which allowed it to reach a speed of 275 km/h on a circuit like Mugello (Italy).

Vincenzo De Silvio, Ducati Technical Director: “For Ducati, having the opportunity to become suppliers of the FIM MotoE World Cup is not only a technologically exciting venture but also the best way to interpret the challenges of the new millennium. Racing competition represents the ideal terrain on which to develop innovative technologies that will then transfer to production motorcycles. At this moment, the most important challenges in this field remain those related to the size, weight, autonomy of the batteries and the availability of the charging networks. Ducati’s experience in the FIM MotoE World Cup will be a fundamental support for product R&D, together with the physiological evolution of technology and chemistry. Helping the company’s internal expertise to grow is already essential today to be ready when the time comes to put the first street electric Ducati into production.”

World Cup will be a fundamental support for product R&D, together with the physiological evolution of technology and chemistry. Helping the company’s internal expertise to grow is already essential today to be ready when the time comes to put the first street electric Ducati into production.”

The mix of expertise, passion, and work of the Ducati MotoE team has led to the birth of an electric motorcycle with unique technical solutions. Starting with the battery pack, the most binding and characterizing element in terms of masses and dimensions, which on the Ducati MotoE is characterized by a shape specifically designed to follow the natural course of the middle area of the bike. The battery pack weighs 110 kg and offers a capacity of 18 kWh with a 20-kW charging socket integrated into the tail. Inside there are 1,152 cylindrical cells of the “21700” type.

The inverter, with a low weight of 5 kg, is a unit derived from a high-performance model used in motor racing for electric vehicles, while the motor (21 kg weight and a maximum rotation speed of 18,000 rpm) was developed by a partner following the technical specifications provided by Ducati. The entire system is based on a voltage of 800V (with a fully charged battery pack) to maximize the output of the electric powertrain and, as a consequence, performance and range.

One of the most advanced technical solutions tested on the Ducati MotoE concerns the cooling system. The prototype components are in fact cooled by a particularly sophisticated and efficient liquid system with a double circuit designed to meet the different thermal needs of the battery pack and the motor/inverter unit. This guarantees extreme regularity of temperatures with important benefits in terms of consistency of performance but also in charging times. In fact, it is not necessary to wait for the battery pack to cool to start the process: the Ducati MotoE can be charged as soon as it enters the garage, and it takes about 45 minutes to recharge it up to 80% of its range.

The carbon fibre case of the battery pack also acts as a stressed part of the chassis, like what happens for the Ducati Panigale V4 engine, with an aluminium monocoque Front Frame for the front area weighing 3.7 kg. The rear is composed of an aluminium swingarm weighing 4.8 kg with a geometry like that of the Ducati Desmosedici racing in MotoGP. The rear subframe, which integrates the tail and the rider seat, is made of carbon fibre.

The suspension area features an Öhlins NPX 25/30 pressurized fork with 43 mm diameter upside-down tubes at the front, derived from the Superleggera V4, while an Öhlins TTX36 shock absorber is present at the rear and is fully adjustable. The steering damper is an adjustable Öhlins unit.

The braking system is supplied by Brembo and is sized for the specific requirements of the Ducati MotoE. At the front it is composed of a double steel disc with a diameter of 338.5 mm of increased thickness, which has fins on the internal diameter with the aim of increasing the thermal exchange surface area and improve disc cooling in conditions of extreme use on the track. On this double disc operate two GP4RR M4 32/36 calipers with a PR19/18 radial master cylinder. At the rear, the P34 caliper acts on a single disc unit 220 mm in diameter and 5 mm thick with a PS13 master cylinder. Teams can also choose to equip their bikes with an optional rear brake control positioned on the left handlebar, which the rider can use as an alternative to the pedal one.

The braking system is supplied by Brembo and is sized for the specific requirements of the Ducati MotoE. At the front, it is composed of a double steel disc 338.5 mm in diameter with a thickness currently in the selection phase between measurements of 6.8 and 7.4 mm, which has fins on the internal diameter with the aim of increasing the thermal exchange surface area and improve the cooling of the disc in conditions of extreme use on the track. Two GP4RR M4 32/36 calipers with PR19 x 18 radial master cylinder operate on this double-disc. At the rear, the P34 caliper. Teams can purchase an optional rear brake control positioned on the left handlebar, which the rider can use as an alternative to the pedal one.

Roberto Canè, Ducati eMobility Director: “I remember the birth of the MotoE project and every phase of the composition of the work team well, with the involvement of Ducati Corse colleagues and the search for contacts within the Volkswagen Group who could give us suggestions on how to develop this project. To make this bike we followed the same procedure that we usually follow on a production bike. We started by defining the design of the bike and in parallel, the technical office began to design the various vehicle components. The initial brief was to create a racing bike that respected the minimum performance characteristics required by Dorna. As a matter of fact, this project has made and is making the whole team involved fall in love and is pushing us to create a bike with better characteristics than initially requested by the organizer “.

The development process of the Ducati MotoE also involved the Ducati Corse test team led by Marco Palmerini, who worked on the track applying the same methodologies used in MotoGP, thanks also to the support of the riders Michele Pirro, Alex De Angelis, and Chaz Davies. Through the work on the electronics, the aim was to obtain a throttle response like that of an endothermic unit and a response from the electronic controls (such as Ducati Traction Control, Ducati Slide Control, Ducati Wheelie Control, and throttle/engine brake maps) indistinguishable from that of the racing bikes that Ducati riders are used to.

The possibility of applying the development and test method already used in MotoGP, with a precise sequence of tests to be carried out on the various components to maximize the performance of each day on the track, was achieved also thanks to the efficiency of the cooling system, which has reduced charging times to a minimum, thus allowing for a truly significant continuity of use for an electric motorcycle. The development work involved a specific learning and training course for all the personnel involved, exploiting the knowledge shared within the Volkswagen Group, to ensure the total safety of the rider and technicians.

The fact that Ducati belongs to the Volkswagen Group, which has made electric mobility an essential element of its “New Auto” 2030 strategy, represents the best prerequisite for an extraordinary exchange of expertise in the field of electric powertrains. Ducati is in close contact with the Group’s centres of expertise and with the Centre of Excellence (CoE) at Salzgitter in Germany, but also with other brands of the Group such as Porsche and Lamborghini.

The work plan of the Ducati MotoE project has already reached an advanced stage of development and is proceeding at a rapid pace towards 2023, the year in which Ducati will take on the role of sole supplier of the FIM MotoE World Cup with 18 electric motorcycles on the track every weekend. The next objective for the Bologna-based manufacturer is to take advantage of participation in the most important racing competition in the world for electric motorcycles to experiment with innovative technologies, train new skills and study how to create, as soon as the technology will allow, a Ducati electric vehicle that is sporty, light, exciting and able to satisfy all enthusiasts.

More pictures and information on the Ducati MotoE are available on Ducati Media House. #DucatiMotoE

Become a Motorcycle.com insider. Get the latest motorcycle news first by subscribing to our newsletter here.

The post WORLD EXCLUSIVE: Ducati V21L MotoE Prototype – First Look appeared first on Motorcycle.com.

Copyright

© Motorcycle.com